- Home

- Building Module

Overviews

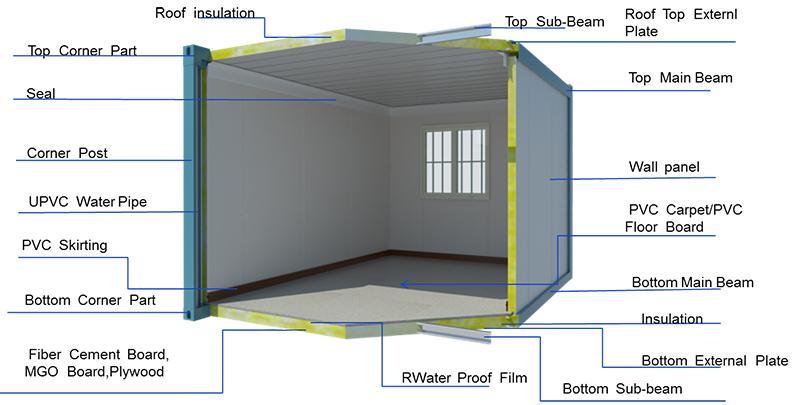

Utilizing steel shipping containers, modular buildings are composed of a roof panel, floor board, corner posts, and wall panels. The lightweight yet strong components of the shipping containers facilitate modular design and manufacturing that are perfect for low cost structures that can be assembled in seemingly no time.

Flat pack containers meet the structural standards of a wide range of international governing bodies. All other components of the buildings are installed at the construction site. Wall and roof panels, windows, doors, and joint fittings will be packed within the containers before shipping. Once the containers are delivered, our engineers will assemble them on-site based on the approved interior design scheme.

Application

Container units are designed to be stackable, portable, versatile, and functional. No components are lost during assembly or disassembly. The modular structure can be moved an unlimited number of times. They can be assembled to include office space, bedrooms, dining rooms, bathrooms, entertainment rooms and so on.

GS Housing modular buildings can be designed as up to three-floor structures with no limitation on width. Therefore, modular buildings can be manufactured as many kinds of temporary buildings, such as construction camps, military housing, schools, hospitals, and transitional housing particularly for emergency situations.

Container structures are made from durable steel with a designed useful life of at least 20 years. The convenience and portability of the buildings makes them highly versatile.

Construction camp

Construction camp Modular construction house

Modular construction house Containerized relocatable buildings

Containerized relocatable buildings

Container office

Container office Temporary school buildings

Temporary school buildings Modular hotel buildings

Modular hotel buildings

Our flat-pack container structures are certified and delivered as standardized ISO intermodal containers, the most proven freight unit in the world today.

Standard dimensions

External dimension: 6055mm* 2435mm* 2896mm (length*width*height)

Internal dimension: 5845mm* 2225mm* 2780mm (length*width*height)

Tare: 2000 KG

Through the flat packaging, 4 cases of combined transport can be realized.

According to the wall structure form, it can be classified as a colored sandwich board panel container house, or a wooden frame and plate composite wallboard container house.

Shipping and delivery

The standard container that makes up the modular structure is suitable for international transport. It features appropriate external dimensions and has connections for lifting, fixing, or compounding. The container is designed as a light construction structure consisting of floor and roof frames and corner profiles. The construction enables compounding of individual containers in longitudinal and transverse directions without limits. It also enables compounding of containers in 2 floors in height (ground floor + first floor), or in 3 floors in height for warehousing of these containers (ground floor + 2floor).

The wainscots of the container are made of light insulation panels and offer pleasant climate inside due to their physical properties.

Delivery: Containers can be delivered assembled or individually in kits 660mm high. 4 kits can be bundled in packages 2640 mm high (ISO container dimensions)

Features of container

1. Container adopts hot rolled galvanized steel sheet for its frame, and incombustible materials for its walls. Meanwhile, all the basic designs, such as water heating, electrical appliances, and interior furnishing, are provided by our professional team and manufactured beforehand in our factory. No need for extra processing, they can be put to use after assembly.

2. Containers are easily assembled and disassembled in a short period of time. It could also be relocated according to customer requirements.

3. Heat preservation and sound insulation:

Wall panels adopt sandwich panels, which ensure good performance in moisture resistance, and heat insulation.

4. Containers can be used separately or be modularly designed as or multi-story buildings (up to 3). They could also be combined vertically or horizontally to meet the varying demands of the end users.

5. As containers are made from steel, they will withstand relatively powerful earthquakes.

6. Containers are pre-fabricated and possess great design flexibility with excellent energy saving properties, making the structures incredibly eco-friendly.

Flat pack container composition

Steel framework

Material: 3mm thick Q235A steel for top framework and corner posts; 3.5mm thick Q235A Steel for main bottom framework and 3mm thick Q235A Steel for bottom cross beam

Surface processing: electric galvanization min 6~8μm, zinc compatible epoxy ground coat in a thickness of 20~ 30μm , final zinc compatible vinyl acrylic coat/chlorinated rubber paint in a thickness of 50~70μm.

Fittings: 8 corner fittings (dimensions according to ISO standard 1161), rainwater pipe in the roof framework, plate thickness of 10mm excluding top corner fittings of the top kit of each bundle (20mm thickness)

Floor Composition

-external wainscot: flat galvanized steel sheet metal with thickness of 0.5mm.

-insulation filling: noncombustible glass wool in a thickness of 100 mm among steel transverse supports. Insulation density: 14Kg/m3

-steam blockade: PE foil in a thickness of 80μm

- Fiber cement board in a thickness of 20mm

-glued PVC flooring covering in a thickness of 1.9mm.

Permitted loading: 2.50 KN/m2

Coefficient of thermal conductivity: K=0.039 W/mK

R value (Thermal Resistance) = 2.56 m2K/W

Ceiling composition

-external wainscot: flat galvanized and painted steel sheet metal with a thickness of 0.5mm.

-insulation filling: noncombustible glass wool in a thickness of 100mm among plywood purlins. Glass wool density: 14 Kg/m3

-steam blockade: PE foil in a thickness of 80μm

-inner wainscot: particle board panel with a thickness of 9 mm with a white foil; joining of particle board panels with PVC profiles

Water outlet: corner pillars 4 each of PVC rainwater pipes, diameter 40mm in

Permitted loading: 2.0 KN/m2

Coefficient of thermal conductivity: K=0.04 W/mK

R value (Thermal Resistance) = 2.56 m2K/W

Wall panel

Side panel width: 1150mm; total panel thickness: 75mm. Five panels fit into the long side and two panels fit into the short side of the container and they are fully interchangeable. Note: If there are cables assembled in roof and wall panels, then the panels cannot be replaced, they should be assembled according to the electrical layout.

Composition

-External wainscot: galvanized and painted steel sheet metal in a thickness of 0.5mm.

-Insulation filling: 75mm glass wool panel

-Inner wainscot: galvanized and painted steel sheet metal in a thickness of 0.45mm.

Permitted loading: 0.5 KN/m²

Coefficient of thermal conductivity: k =0.039 W/mK

R value (Thermal Resistance) = 1.54 m2K/W

Doors

Standard external door: Single fold, 75mm thick, made of: a frame in painted steel hot galvanized and painted steel sheets on both sides

Nominal dimensions 850×2035mm, internal clearance dimensions 760 x1990 mm. furnished with a handle lock with 3 keys.

Windows

Sliding window: made of PVC, with dimensions 1150×1100mm, glazed with double layer glass in a thickness of 5mm, with

sliding" mechanism (one side fixed and one sliding)

Rolling shutter external PVC rolling shutters.

Electrical installations

Standard: according to VDE 100 and CE regulations

Voltage: 220 V, 50 Hz single phase

External connections: CE E-connection plus/socket, 3-pole 32 A, 220V~, mounted on the top frame in upper corners of a shorter side wall

Inner distribution system: BVVB cables of suitable dimensions (6,4,2.5, 1.5 mm2), CE marked, flush-mounted.

All cables (located on the ceiling and inside wall panels) run into CE certified plastic conduits. Roof cables and panel cables are connected with CE compliant "jacks". All jack connections are protected inside CE marked and IP44 rated distribution boxes.

Protection: protective current switch (40/2E-0,03A), automatic fuses (B-characteristics) of suitable power (10A/1P, 16A/1P)

Grounding: galvanized connector with a steel plate of dimensions 50x20mm welded on the bottom frame

Fittings

-Electric distribution box-1×40/2E-0.03A (protective current switch), 1×10A & 2×16A (automatic fuses)

-double fluorescent lights 2×40W 220V-2 each

- Sockets 220 V-4 each

- Switches 220 V-1 each

Accessories

Industrial socket

Concave corner part

Skirting corner part

5 hole socket

Double open switch

Skirting line (white or wood grain brown)

Concave line

Top triangle plate

Pan sink (Galvanized)

Bolts & nuts

Screw Sheeting

Warranty

Complete - All components have a 1 year warranty.

Possibility of container mounting

-on a flat solid surface (asphalt, concrete …)

-on point foundations (concrete cubes, dimensions 60/60/30cm, 6pcs/20' container)

-on band foundations (concrete band, 60cm wide, on the container circumference)

Remark: rights to change technical parameter are withheld.