- Home

- Building Module

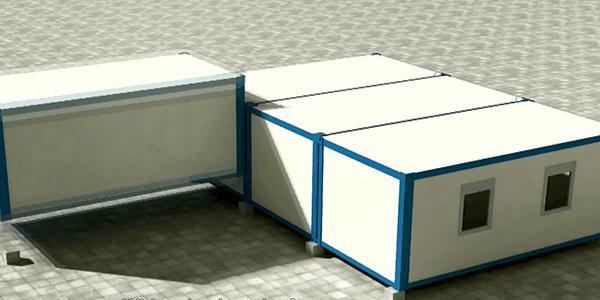

- Flat pack container installation

Modular buildings produced by GS housing are specially designed and manufactured for quick and safe installation nearly anywhere. The entire flat pack container installation process can be completed in only 3-4 hours by 4 workers. The installation of these modular structures can be performed with minimal noise and zero waste. Our technology and highly skilled workers lead to a professional installation each time.

Possibilities of container mounting

-on a flat solid surface (asphalt, concrete …)

-on point foundations (concrete cubes, dimensions 60/60/30cm, 6pcs/20' container)

-on band foundations (concrete band, 60cm wide, on the container circumference)

It is quite easy!

1. Open the packed container, and put roof boarding aside

1. Open the packed container, and put roof boarding aside 2. Fix the bottom part

2. Fix the bottom part

3. Install the top rails

3. Install the top rails 4. Install the wall panel

4. Install the wall panel

5. Fix them with glue

5. Fix them with glue 6. After installing the water heating and electric heating system and fixing the frame, a flat pack container’s installation is finally completed.

6. After installing the water heating and electric heating system and fixing the frame, a flat pack container’s installation is finally completed.

7. When installing a modular building, we need to ensure that there is a 12mm gap between containers. Meanwhile, the layout of the modular building should be designed according to the customer’s construction site. When installing a two-floor or even three-floor modular building, the frame should be installed with the help of a crane. This is the only way a modular construction unit can be completed.

We also provide interior design for our customers. After decoration, the flat pack container segments can be redesigned as kitchens, bathrooms, bedrooms and so on.

About electrical installations

Standard: according to VDE 100 and CE regulations

Voltage: 220 V, 50 Hz single phase

External connections: CE E-connection plus/socket, 3-pole 32 A, 220V~, mounted on the top frame in upper corners of a shorter side wall

Inner distribution system: BVVB cables of suitable dimensions (6,4,2.5, 1.5 mm2), CE marked, flush-mounted.

All cables (located on the ceiling and inside wall panels) run into CE certified plastic conduits. Roof cables and panel cables are connected with CE compliant "jacks". All jack connections are protected inside CE marked and IP44 rated distribution boxes.

Protection: protective current switch (40/2E-0,03A), automatic fuses (B-characteristics) of suitable power (10A/1P, 16A/1P)

Grounding: galvanized connector with a steel plate of dimensions 50x20mm welded on the bottom frame